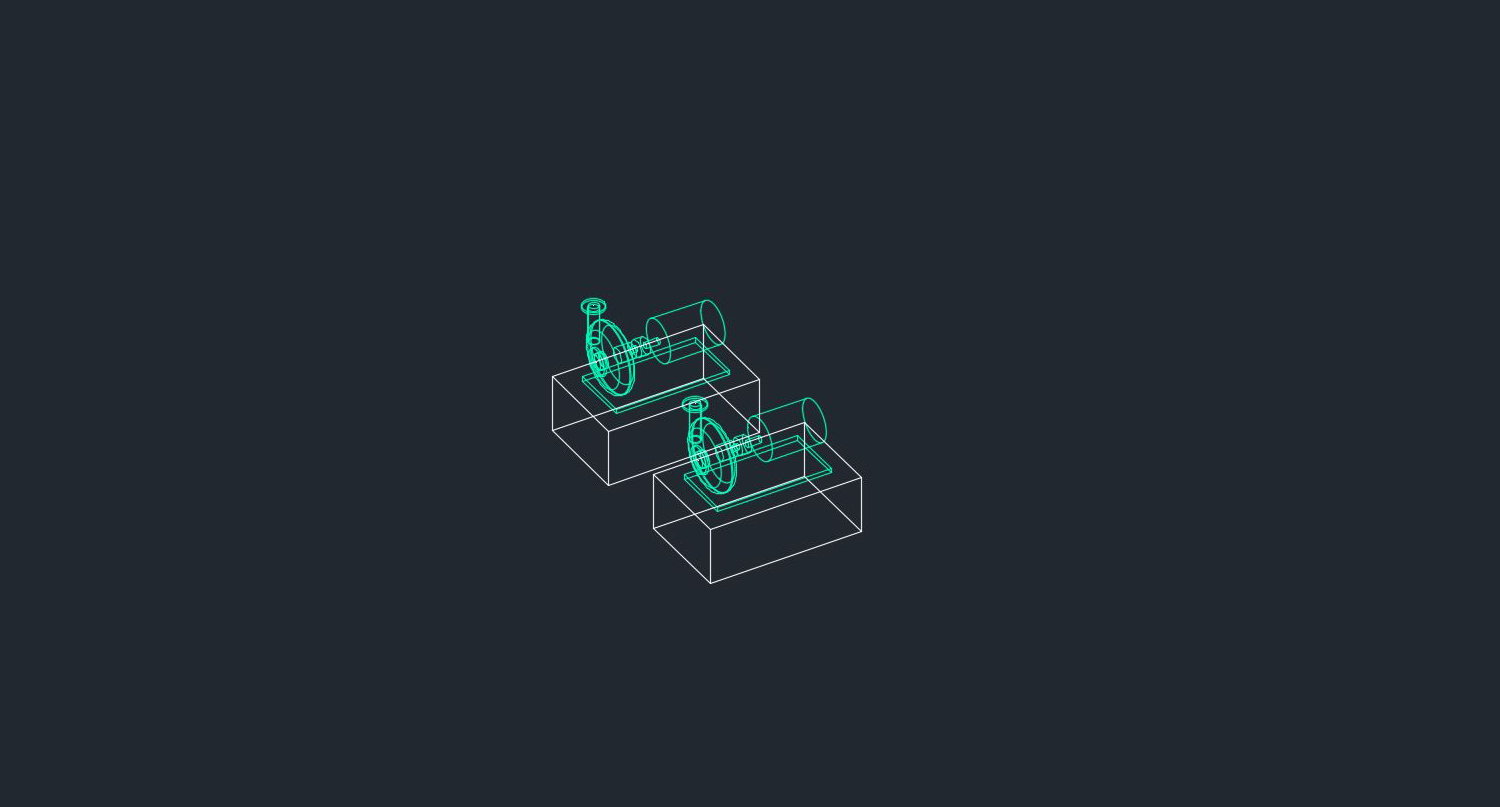

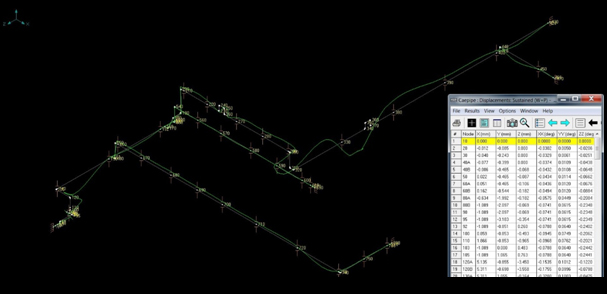

Jet Fuel Piping Stress Analysis And Modification (ASME B31.1)

Design and stress analysis of Jet Fuel piping. Determination of types and locations of supports, pump nozzle stress check tasks are completed.

Client : BTB Construction & Installation

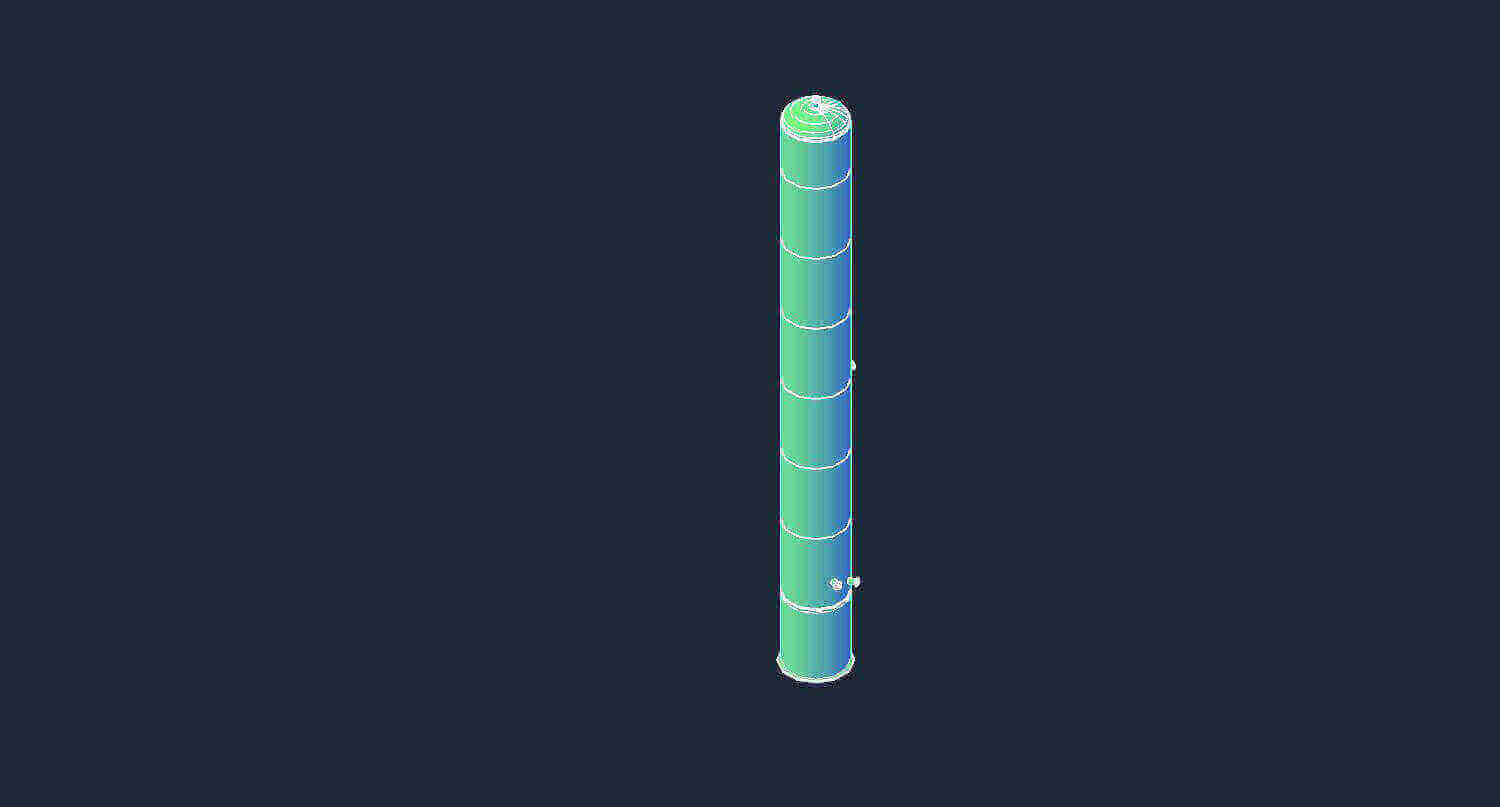

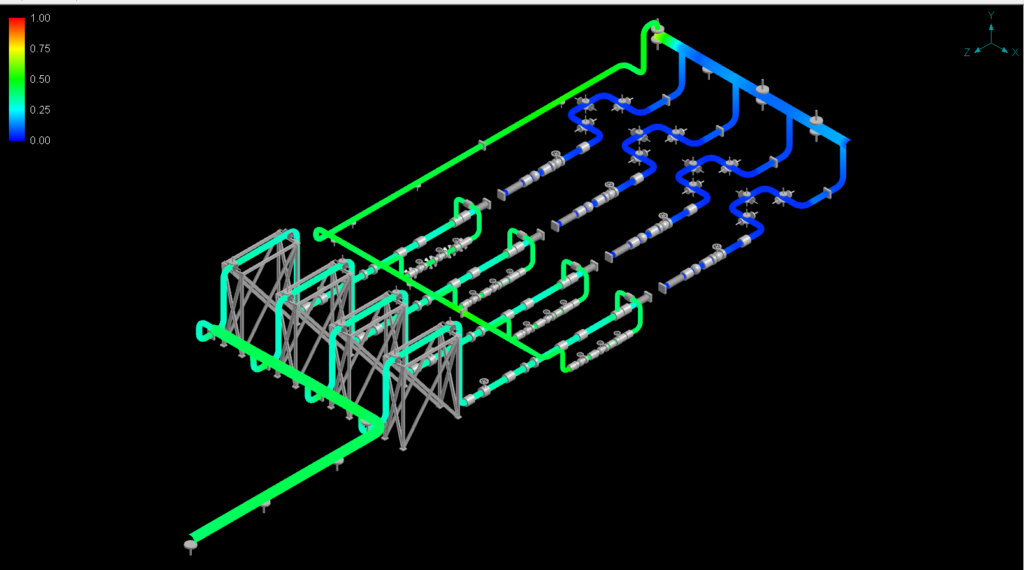

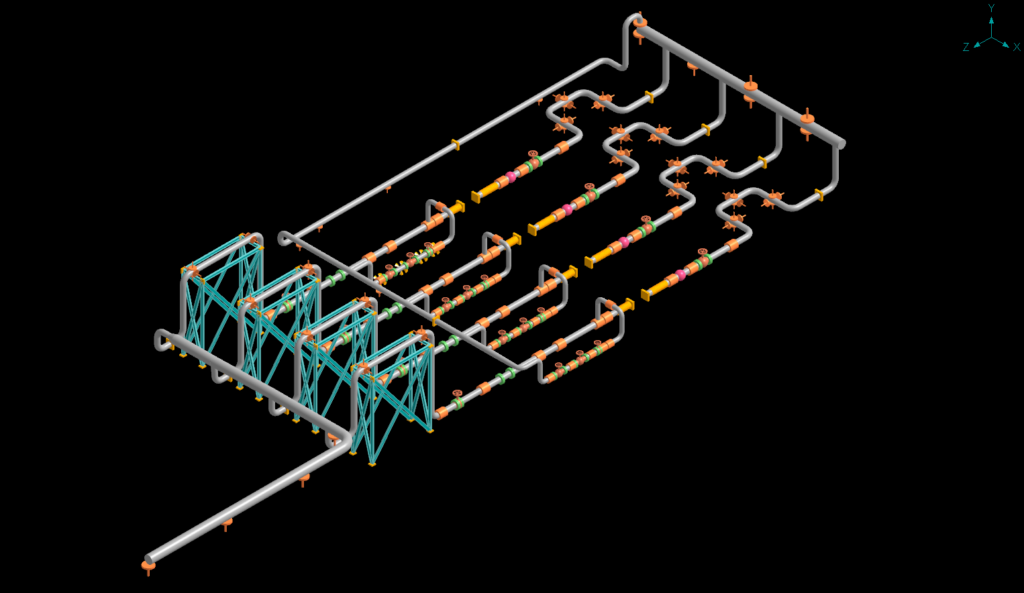

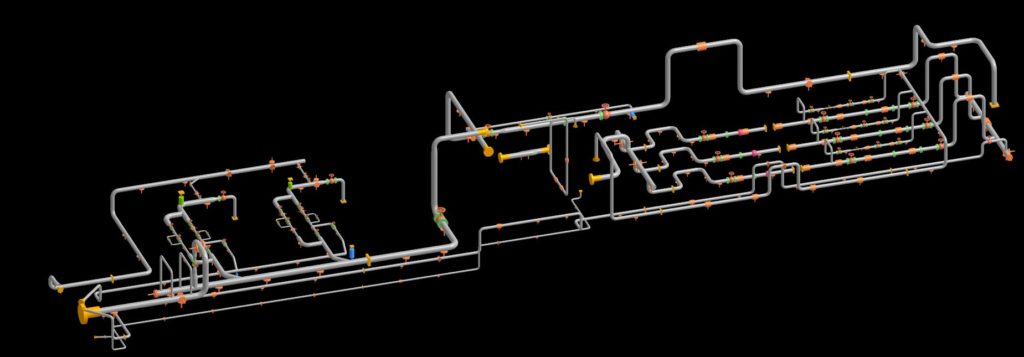

Wellhead Production&Separation Piping Design and Stress Analysis (ASME B31.1)

Design and stress analysis geothermal power plant’s reinjection pumps piping system.Pressure 39 bar Temperature 190 C.

Static Stress Analysis : Determination of types and locations of supports, pump nozzle stress check tasks are completed. Nozzle stress checks of accumulation tanks and seperator tower. Pipe rack stress analysis tasks and determination of steel beam sections are completed

Client : ENPRODE Engineering & Construction

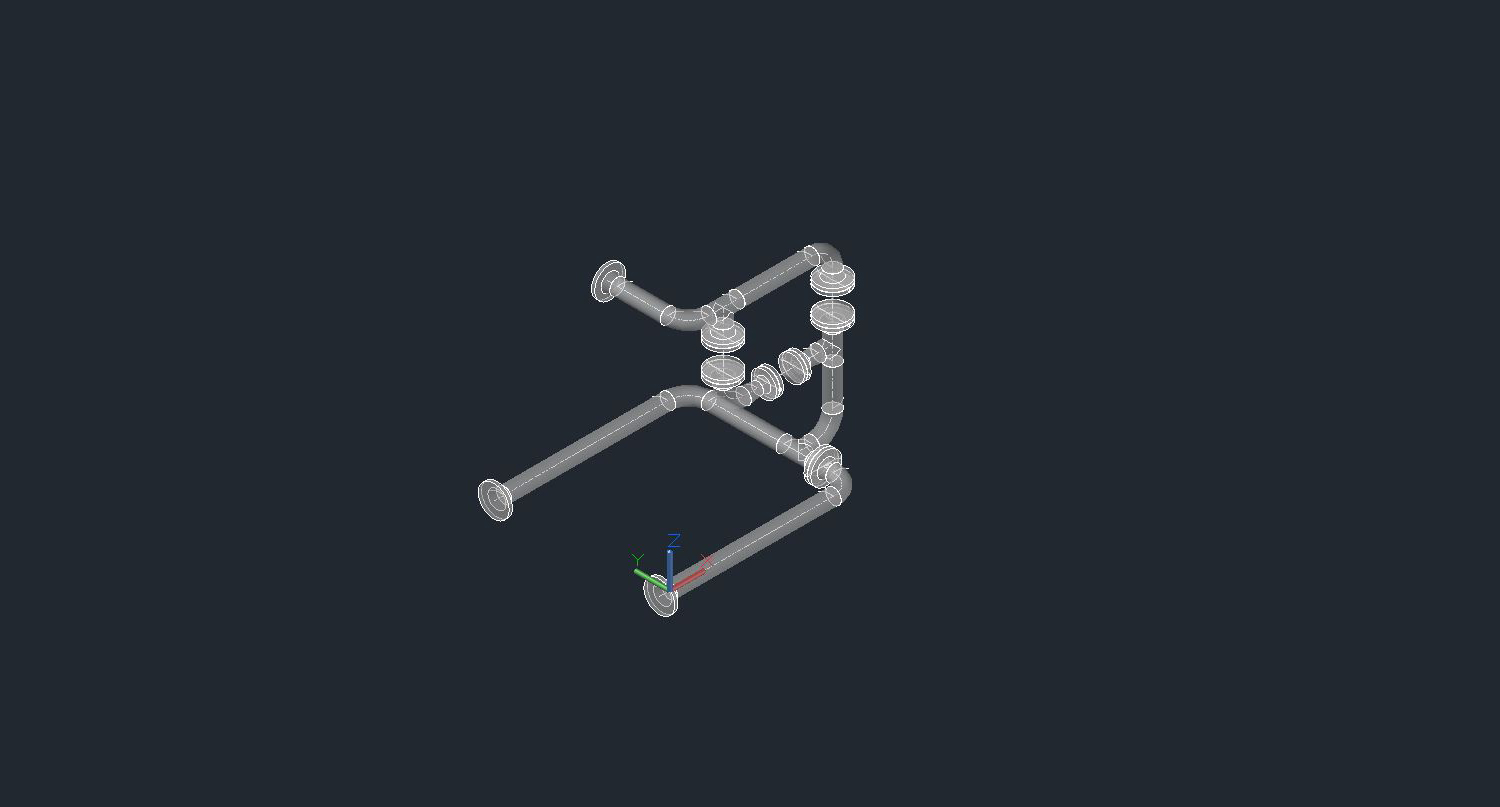

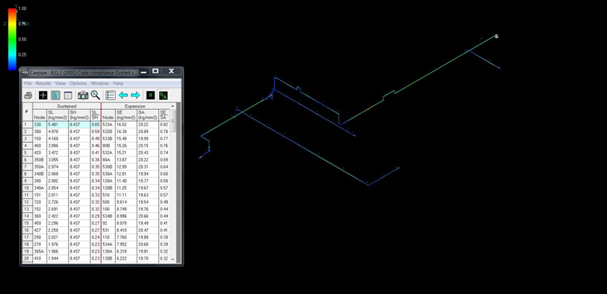

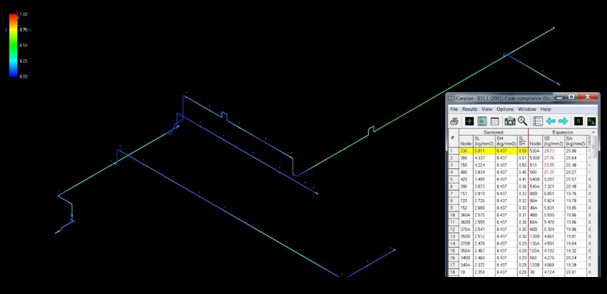

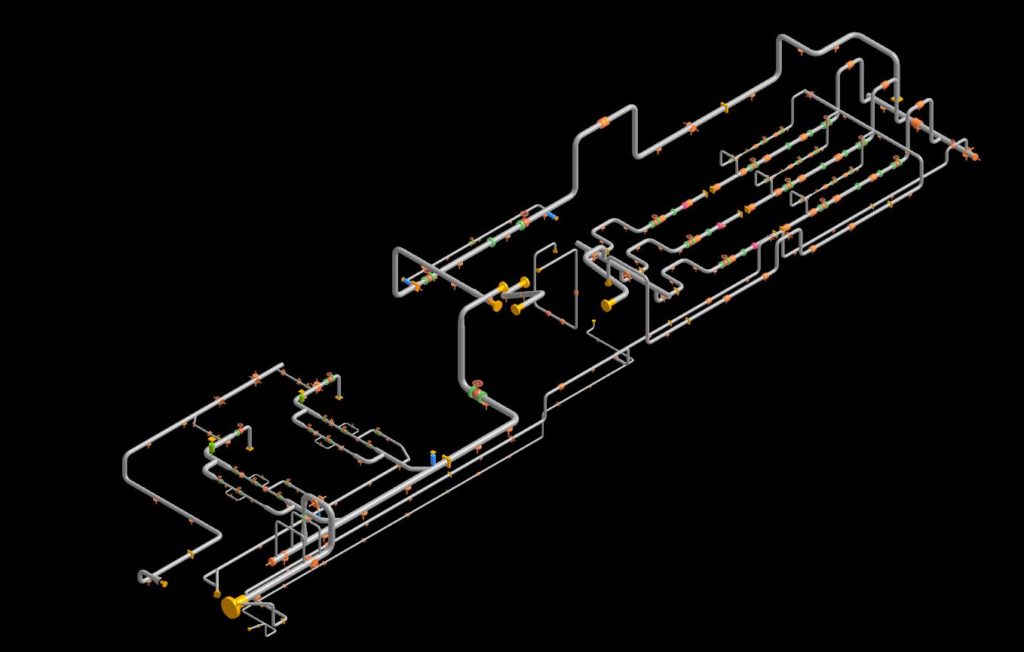

Brine, Steam and Condensate Line Stress Analysis And Modification (ASME B31.1)

Design and stress analysis geothermal power plant piping system.

Static Stress Analysis : Determination of types and locations of supports, pump nozzles, accumulation tank nozzles, seperator column nozzle stress check tasks are completed. Pressure 82 bar Temperature 120 C

Dynamic Analysis : Modal analysis of vibrations on brine wells. Selection of spring hangers accordingly with vibration analysis results.

Client : ENPRODE Engineering & Construction

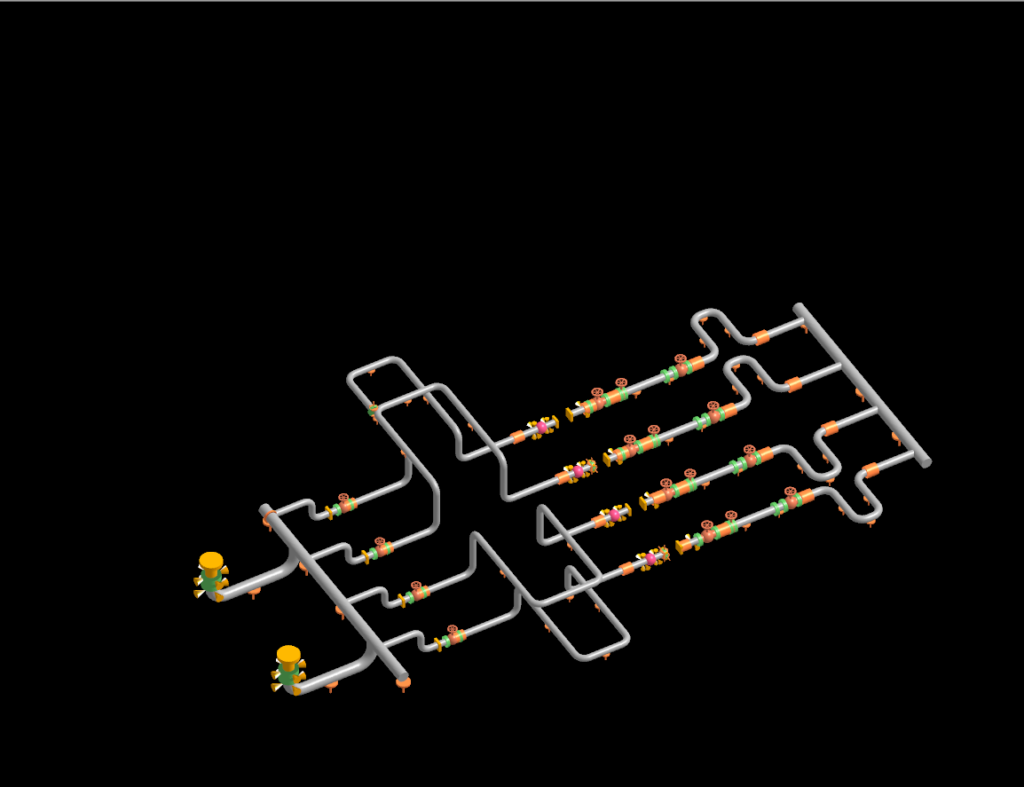

Wellhead Production&Separation Piping Design and Stress Analysis (ASME B31.1)

Design and stress analysis geothermal power plant’s reinjection pumps piping system.Pressure 39 bar Temperature 190 C.

Static Stress Analysis : Determination of types and locations of supports, pump nozzle stress check tasks are completed. Nozzle stress checks of accumulation tanks and seperator tower. Pipe rack stress analysis tasks and determination of steel beam sections are completed

Client : ENPRODE Engineering & Construction

Wellhead Production&Separation Piping Design and Stress Analysis (ASME B31.1)

Design and stress analysis geothermal power plant’s reinjection pumps piping system.Pressure 39 bar Temperature 190 C.

Static Stress Analysis : Determination of types and locations of supports, pump nozzle stress check tasks are completed. Nozzle stress checks of accumulation tanks and seperator tower. Pipe rack stress analysis tasks and determination of steel beam sections are completed

Client : ENPRODE Engineering & Construction

Wellhead Production&Separation Piping Design and Stress Analysis (ASME B31.1)

Design and stress analysis geothermal power plant’s reinjection pumps piping system.Pressure 39 bar Temperature 190 C.

Static Stress Analysis : Determination of types and locations of supports, pump nozzle stress check tasks are completed. Nozzle stress checks of accumulation tanks and seperator tower. Pipe rack stress analysis tasks and determination of steel beam sections are completed

Client : ENPRODE Engineering & Construction

Wellhead Production&Separation Piping Design and Stress Analysis (ASME B31.1)

Design and stress analysis geothermal power plant’s reinjection pumps piping system.Pressure 39 bar Temperature 190 C.

Static Stress Analysis : Determination of types and locations of supports, pump nozzle stress check tasks are completed. Nozzle stress checks of accumulation tanks and seperator tower. Pipe rack stress analysis tasks and determination of steel beam sections are completed

Client : ENPRODE Engineering & Construction

Wellhead Production&Separation Piping Design and Stress Analysis (ASME B31.1)

Design and stress analysis geothermal power plant’s reinjection pumps piping system.Pressure 39 bar Temperature 190 C.

Static Stress Analysis : Determination of types and locations of supports, pump nozzle stress check tasks are completed. Nozzle stress checks of accumulation tanks and seperator tower. Pipe rack stress analysis tasks and determination of steel beam sections are completed

Client : ENPRODE Engineering & Construction

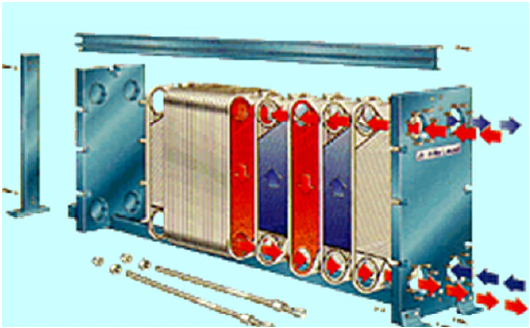

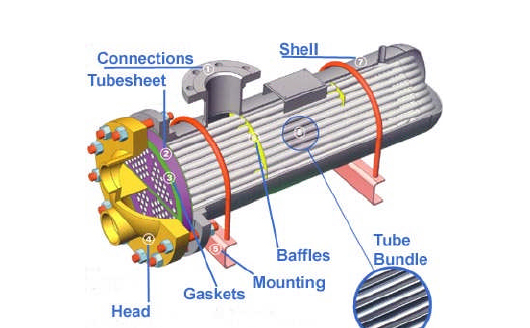

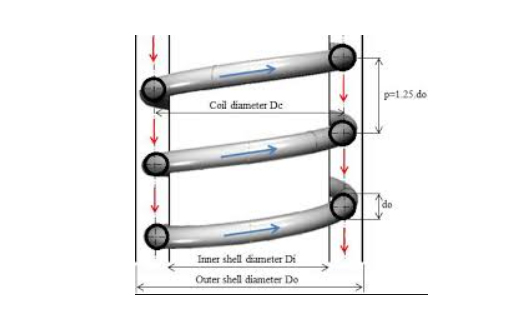

Sizing of 85 Tons/hour hot water exchanger for HEPP.

85 tons/hour 30 C hot water cooling down to 23 C where the raw water temperature is 20 C. A Plate, Shell & Tube, Submerged Pipe Coil Type heat exchangers are modelled. Submerged Pipe Coil Type heat exchanger modelled in Ansys for CFD and heat transfer.

Client : BTB

Sizing of 85 Tons/hour hot water exchanger for HEPP.

85 tons/hour 30 C hot water cooling down to 23 C where the raw water temperature is 20 C. A Plate, Shell & Tube, Submerged Pipe Coil Type heat exchangers are modelled. Submerged Pipe Coil Type heat exchanger modelled in Ansys for CFD and heat transfer.

Client : BTB

Sizing of 85 Tons/hour hot water exchanger for HEPP.

85 tons/hour 30 C hot water cooling down to 23 C where the raw water temperature is 20 C. A Plate, Shell & Tube, Submerged Pipe Coil Type heat exchangers are modelled. Submerged Pipe Coil Type heat exchanger modelled in Ansys for CFD and heat transfer.

Client : BTB

Sizing of 85 Tons/hour hot water exchanger for HEPP.

85 tons/hour 30 C hot water cooling down to 23 C where the raw water temperature is 20 C. A Plate, Shell & Tube, Submerged Pipe Coil Type heat exchangers are modelled. Submerged Pipe Coil Type heat exchanger modelled in Ansys for CFD and heat transfer.

Client : BTB

Sizing of 85 Tons/hour hot water exchanger for HEPP.

85 tons/hour 30 C hot water cooling down to 23 C where the raw water temperature is 20 C. A Plate, Shell & Tube, Submerged Pipe Coil Type heat exchangers are modelled. Submerged Pipe Coil Type heat exchanger modelled in Ansys for CFD and heat transfer.

Client : BTB

Sizing of 85 Tons/hour hot water exchanger for HEPP.

85 tons/hour 30 C hot water cooling down to 23 C where the raw water temperature is 20 C. A Plate, Shell & Tube, Submerged Pipe Coil Type heat exchangers are modelled. Submerged Pipe Coil Type heat exchanger modelled in Ansys for CFD and heat transfer.

Client : BTB